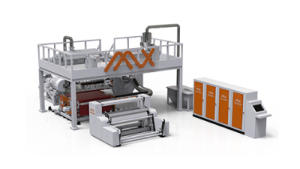

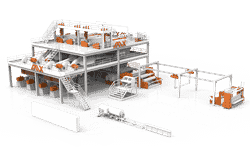

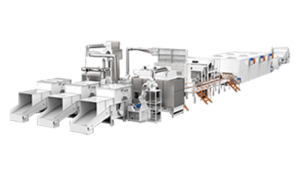

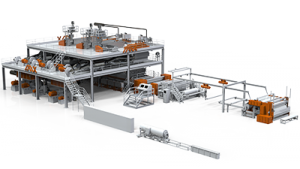

In order to ensure the continuous and stable operation of the melt-blown non-woven machine, before using the melt-blown non-woven machine, you must have a very comprehensive understanding of the operation and use of the melt-blown non-woven fabric machine, otherwise, the wrong operation may cause the equipment to operate very badly and big damage. The following is the correct debugging method of the meltblown nonwoven machine.

1. Turn on the start-stop switch and the power switch, the built-in light of the power switch is on.

2. Adjust the air pressure: the air pressure valve is under the worktable, you can see the air pressure valve by opening the door of the meltblown non-woven fabric making machine. Adjust the pressure according to the actual situation. When some mechanisms are not synchronized, increase the pressure. The working air pressure is generally adjusted within the range of 0.2~0.6MPa.

3. Sound wave inspection and adjustment: (when the meltblown nonwoven fabric machine is stopped)

(1) Turn on the power switch of the ultrasonic generator and press the “Sound wave test” switch. If the amplitude indicator rises sharply and exceeds 100, it means that the frequency is too far from the resonance point, and the “Sound wave adjustment” knob must be adjusted. Observe the amplitude display, press the “Sound Wave Inspection” check the switch with the left hand (not more than 3 seconds), and turn the “Sound Wave Adjustment” knob with the right hand to adjust the pointer of the amplitude display to the low point.

When adjusting, if the amplitude indicator does not fall but rises, turn the “sound wave adjustment” knob in the opposite direction. The reading of the amplitude indicator is within 50, and the reading of the ammeter indicator is below 0.6A, which is a good working condition. After adjusting the sound wave, tighten the butterfly nut and close the protective cover.

(2) During the no-load test, if the “overload indicator light” is on, it means there is a problem with the meltblown non-woven fabric making machine. At this time, it is not allowed to start work, you must shut down and check the cause, and then start work after troubleshooting.

3. Inspection of the cooling fan. Check whether the cooling fan is working normally to ensure that the meltblown non-woven fabric-making machine can work for a long time when it is working.

Before the operation of the meltblown non-woven fabric machine, check whether the various parts of the machine are normal or not. At the same time, the aging or damaged parts should be replaced in time. If the meltblown nonwoven fabric machine is found to be malfunctioning during the operation, it should be stopped immediately and eliminated. It can be turned on and work after the failure.

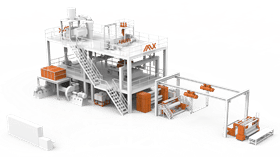

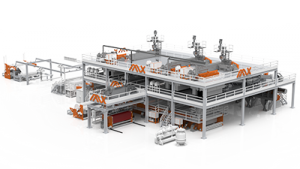

There are many things to pay attention to during the debugging process of the meltblown nonwoven machine. If we don’t pay attention, it may cause production failure and cause equipment accidents. If the above methods are not very helpful to you, you can get more solutions by contacting us, and we also have a professional meltblown non-woven fabric production line.

As a professional manufacture of reliable nonwoven machines, we adhere to the “quality-oriented, service-oriented” concept to provide high-quality products and services to users all over the world. If you want to buy our high-quality meltblown non-woven fabric machine, please contact us in time!