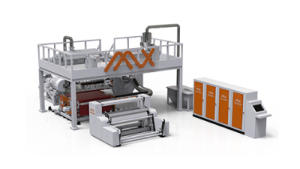

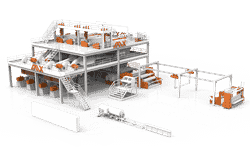

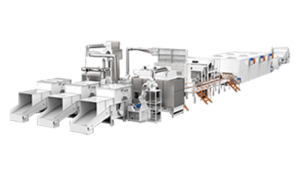

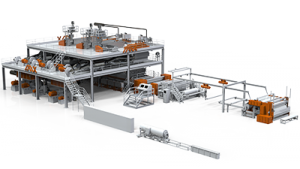

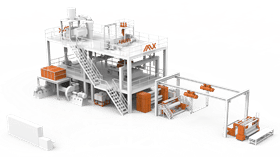

The core components of the melt blown non-woven fabric machine ensure the normal production of the melt blown cloth, which is indispensable in the manufacturing process of the melt blown cloth. The following are the three core parts of meltblown non-woven fabrics.

Spinneret The spinneret for melt spinning is a representative spinneret for the manufacture of synthetic fibers such as polyester and nylon. The thermoplastic resin is heated and melted, extruded through the spinneret in air or water at a certain speed, and cooled. Spinning method of coagulation into fibers.

The core technology is the small nozzle on the spinneret. This nozzle is not only small in size but also has a complicated hole pattern on such a small nozzle, which is extremely difficult to process. The nozzle processing process takes several months. If the processing accuracy is not high, the final meltblown cloth produced will not meet the corresponding technical requirements, which will affect the protective performance of the mask.

Meltblown die head The die head includes a die head body, a spinneret, and an air plate. The spinneret and the gas plate are detachably installed in the main body of the die, a spinneret hole is arranged in the spinneret, and a number of gap grooves are arranged between the spinneret and the gas plate. A number of gas circulation channels are also opened in the main body of the die head, and the gas circulation channels are communicated with the slit grooves. An air pipe connecting end is arranged on the outer wall of the die main body, and the air pipe connecting end is communicated with the gas collecting cavity through a gas pipe. One end surface of the spinneret hole of the spinneret is fixedly connected with an interval flow stabilizing member, the other end surface of the spinneret hole is fixedly connected with a pipe connection device, and the spinneret hole is connected with the discharge port of the screw extruder through the pipe connection device.

In the melt-blown non-woven machine, the melt-blown die is one of the core components to realize the drawing and molding of the polymer. Its design and accuracy directly affect the length, uniformity, toughness, fineness, and many other aspects of the wire drawing, thereby having a decisive impact on the quality of the final coil.

Melt blown air heater That is the pipeline heater, which consists of two parts: the body and the control system. The heating element is made of stainless steel pipe as a protective sleeve, high-temperature resistance alloy wire, crystalline magnesium oxide powder, formed by a compression process. The control part adopts advanced digital circuits, integrated circuit triggers, high back-pressure silicon controlled rectifiers, etc., with adjustable temperature measurement and constant temperature systems to ensure the normal operation of the electric heater.

Only by understanding the core components of the melt-blown non-woven fabric-making machine in detail can we know its specific operation process. If you want to know more about the meltblown nonwoven fabric machine after reading the above content, you can contact us for more information. At the same time, the meltblown non-woven fabric machine we produce is of high quality and stable operation.

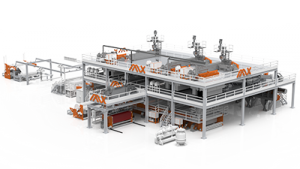

As a professional manufacturer of spunbond non-woven production lines, we have many years of production and manufacturing experience. We have established a complete quality control system and can provide customers with quality-guaranteed products. At the same time, we also provide thoughtful after-sales service and comprehensive solutions. If you are interested in our meltblown non-woven equipment, please contact us immediately!